Pebble Leather: A Complete Guide for Crafters

Walk into any leather workshop, and you'll find a beautiful debate unfolding around pebbled leather. Is that rich, textured surface a sign of a premium, naturally shrunken hide, or is it an artificial pattern designed to cover up flaws? This uncertainty can stop a great project in its tracks. Crafters often ask if the unique grain of leather pebble hides is a mark of quality and worry whether its texture will be a challenge to cut and stitch evenly.

Consider this your definitive guide. We’re here to demystify this versatile material and show you why it’s a favorite for both its durability and style. Together, we'll explore how to spot truly high-quality hides, understand the critical difference between natural pebbling and embossing, and share expert techniques for working with it. You'll leave with the confidence to select the perfect piece and the inspiration to start your next project. No compromises, just real craftsmanship.

Key Takeaways

- Learn to distinguish between the two primary methods used to create the pebbled texture, ensuring you know exactly what you're buying.

- Go beyond the surface with a practical checklist to assess the core quality of any leather pebble hide, guaranteeing a superior final product.

- Pinpoint the ideal projects for this material, from high-wear handbags to elegant upholstery, by leveraging its natural durability.

- Master essential techniques for cutting, marking, and stitching on a textured surface to avoid common frustrations and achieve a professional finish.

What Exactly Is Pebble Leather? Understanding the Textured Classic

When you first start your journey into leathercraft, you'll encounter a world of different textures and finishes. One of the most common and beloved is pebble leather. Simply put, pebble leather is real leather characterized by a distinct, bumpy, raised grain that resembles small pebbles. It's important to know that "pebbled" refers to the texture, not the quality or type of animal hide. This texture is typically embossed onto the hide during the finishing stages of production, a fascinating part of the overall Leather Production Overview. So, to answer a common beginner question: yes, it is almost always genuine leather, prized for its unique combination of softness and strength.

To see this unique texture up close and understand why it's so popular, take a look at this helpful video:

Beyond its handsome appearance, the signature characteristics of a quality leather pebble finish are what make it a crafter's favorite. It’s remarkably durable and forgiving. The raised grain makes it highly resistant to scuffs and scratches, hiding minor wear and tear exceptionally well. This makes it a practical choice for everyday items like bags, wallets, and upholstery that need to withstand the rigors of daily use while maintaining their beauty.

The Look and Feel of a Pebbled Surface

Running your hand over pebble leather is a unique tactile experience. The raised, uneven grain feels supple and substantial. Unlike smooth leather's flat sheen, this textured surface catches and scatters light in multiple directions, giving it a subtle, low-gloss luster that is both sophisticated and understated. In high-quality versions, you’ll notice the pebbled pattern is consistent and uniform across the entire hide, a hallmark of careful craftsmanship.

Pebble Grain vs. Other Leather Textures

Understanding how pebble leather compares to other textures helps you choose the right material for your project. Here’s a quick comparison:

- Smooth Leathers: Unlike the buttery-smooth, flat surfaces of leathers like Buttero or Vachetta, pebble leather has a pronounced, three-dimensional texture.

- Cross-Hatch Grains: It differs from the rigid, geometric pattern of Saffiano leather, offering a more organic and natural-looking grain.

- Naturally Wrinkled Leathers: While it can mimic the look of naturally shrunken hides like goat or deerskin, most pebble leather is embossed for a more consistent and controlled pattern.

How the Pebble is Made: Natural Process vs. Mechanical Embossing

Before you make that first cut, understanding the material in your hands is key to true craftsmanship. The beautiful, tactile surface of leather pebble isn't an accident; it's the result of specific, deliberate processes at the tannery. There are two primary ways this iconic texture is achieved, and knowing the difference will help you appreciate the hide and choose the right piece for your project.

I'm often asked if one method is "better." The honest answer is no. Both natural shrinking and mechanical embossing can produce exceptional, high-quality leather. The real determining factor for quality isn't the texture, but the integrity of the hide it's applied to.

Method 1: The Natural Shrinking Process

This is the old-school, organic method. During the tanning process, specialized agents are introduced that cause the hide's grain structure to shrink and tighten in on itself. As the leather contracts, it naturally forms a dense, pebbled pattern. Because this process relies on the hide's unique fiber structure, the resulting grain is often more random and varied across the skin. This gives it a beautifully authentic character, famously seen in premium articles like German Shrunken Calf (often called Togo leather).

Method 2: Mechanical Embossing or Plating

This method uses precision and power to achieve its effect. A large metal plate, engraved with a pebble pattern, is pressed onto the leather's surface using immense pressure and heat. This process imprints a consistent and highly uniform texture across the entire hide. Embossing can be applied to both top-tier full-grain hides to achieve a specific aesthetic, or to corrected-grain leather, where the natural surface has been buffed to remove major imperfections before the new pattern is applied.

It’s a common myth that an embossed texture is always used to hide flaws. While it can be used for that on lower-grade hides, many of the world's finest tanneries use embossing on their best full-grain skins to create a specific, durable, and uniform finish for luxury goods. Ultimately, whether shrunk or embossed, the quality of the hide beneath is paramount. Developing a feel for these differences is a key part of mastering various Leathercraft Techniques and selecting the perfect material for your project. No compromises.

A Crafter's Guide to Choosing Quality Pebble Leather

The beautiful, textured surface of pebble leather is what catches the eye, but a true artisan knows that the real quality lies beneath. To ensure your project not only looks good but lasts a lifetime, you need to assess the hide's core characteristics. Think of this as your pre-purchase checklist for selecting premium material that honours your craftsmanship.

Inspect the Grain: Full-Grain vs. Corrected-Grain

The grain is the foundation of your leather's character and durability. A genuine full-grain leather pebble surface will still show subtle, natural markings-tiny scars or variations that tell the story of the hide. In contrast, corrected-grain leather has had its surface sanded to remove imperfections before being embossed with a uniform pebble pattern. While clean-looking, it lacks the strength and rich patina potential of full-grain, which will only grow more beautiful with age.

Consider Temper, Thickness, and Tannage

Matching the leather's physical properties to your project is non-negotiable. These three elements are key:

- Temper: This is the leather's stiffness or pliability. A soft temper is perfect for a slouchy tote bag, while a firm temper provides the structure needed for a wallet or clutch that holds its shape.

-

Thickness: Measured in ounces or millimeters, thickness determines the bulk and sturdiness of your piece. As a general guide:

- Wallets & Small Goods: 2-3 oz (0.8-1.2mm)

- Notebook Covers & Clutches: 3-4 oz (1.2-1.6mm)

- Totes & Handbags: 4-6 oz (1.6-2.4mm)

- Tannage: This refers to how the hide was preserved. Understanding the basics of what is leather and its tanning process is crucial. Chrome-tanned leather is typically softer and more color-fast, ideal for upholstery or fashion bags. Vegetable-tanned leather is firmer, has a classic leather scent, and develops a rich patina over time-the choice for heirloom-quality goods.

What to Ask Your Leather Supplier

A reputable supplier will be happy to share details about their hides. Don't hesitate to ask these questions to ensure you're getting exactly what you need:

- Is this leather full-grain or corrected-grain?

- What is its temper (soft, medium, or firm)?

- Can you confirm the exact thickness in mm or oz?

- How would you describe the feel of the finish (e.g., waxy, oily, dry)?

Getting the right answers makes all the difference. Need advice? Book a free consultation with me, Mike! I’m always happy to help you find the perfect hide for your next project.

Best Projects for Pebble Leather: From Handbags to Upholstery

Once you've mastered cutting your leather, the real fun begins: choosing the perfect project. Pebble leather, with its distinctive texture and robust nature, is one of the most versatile materials a crafter can have. Its embossed grain isn't just for looks; it provides a durable, scratch-resistant surface that stands up to daily life. This makes it an exceptional choice for both beginners seeking a forgiving material and seasoned artisans creating high-end goods.

Handbags, Totes, and Backpacks

For items that endure constant use, there’s hardly a better choice. The textured surface of pebble leather is brilliant at hiding the minor scuffs and scratches that everyday bags inevitably collect. It provides enough body to create structured totes that hold their shape beautifully, yet remains pliable enough for more relaxed, unstructured backpacks. It’s no surprise that many luxury brands, from Coach to Michael Kors, rely on this material for their iconic, long-lasting handbags.

Wallets and Small Leather Goods

Think about how often you handle your wallet, keychain, or watch strap. These small items face a surprising amount of wear and tear. Pebble leather excels here because its textured finish maintains its premium look even after being tossed in a pocket or bag day after day. It's an ideal material for crafting durable, handsome pieces that are meant to be used frequently, including:

- Cardholders: Resists warping and scuffs from cards.

- Key Fobs: Stands up to clanking keys and constant handling.

- Watch Straps: Offers a comfortable yet resilient option for daily wear.

- Journal Covers: Protects your thoughts with a durable, tactile cover.

Upholstery and Larger Items

Beyond personal accessories, the resilience of leather pebble makes it a prime candidate for larger, high-impact applications. In upholstery, it’s a fantastic choice for furniture that sees a lot of traffic, like ottomans, dining chairs, or statement armchairs. Its consistent, uniform texture is a major advantage on large surfaces, ensuring a clean and professional finish without the dramatic variations of some natural hides. This same quality makes it a favorite for custom automotive interiors, where durability and a flawless look are non-negotiable.

Whether you're starting with a simple cardholder or tackling a custom chair, pebble leather delivers a blend of real craftsmanship and everyday practicality. Need my advice on selecting the perfect hide for your next project? Browse our hand-selected collection or book a free consultation.

Working with Pebble Leather: Essential Tips & Techniques

Pebbled leather has a rich, tactile character that brings luxury and durability to any project. That beautiful texture, however, can seem intimidating if you're used to working with smooth surfaces. Don't worry. With a few adjustments to your technique, you can master this material and achieve a finish that’s nothing short of professional. Think of it not as a challenge, but as an opportunity to refine your craftsmanship.

Cutting and Skiving the Textured Surface

A clean cut is the foundation of any quality leather good. For a textured surface, this is paramount. The key is to eliminate any chance of the blade snagging or tearing the grain.

- Use a very sharp blade. This is non-negotiable. A fresh scalpel blade or a new rotary cutter blade will glide through the material, preventing ragged edges.

- Cut from the flesh side. Whenever your pattern allows, mark and cut from the smooth, suede-like flesh side. This gives your blade a consistent surface to follow, ensuring greater accuracy than cutting over the uneven grain side.

- Skive with care. When thinning edges for seams, use a sharp skiving knife at a low, consistent angle. The goal is to remove thickness without applying so much downward pressure that you flatten the pebble grain near the edge. Practice on a scrap piece first.

Marking, Stitching, and Assembly

Precision is just as important after the cut. The texture of leather pebble requires a thoughtful approach to marking and assembly to keep your lines clean and your construction solid.

For marking stitch lines, use a wing divider with gentle pressure. You want to create a subtle guide in the "valleys" of the texture, not a deep scratch that damages the peaks. When it comes to adhesives, apply double-sided tape or contact cement only within the seam allowance. This prevents messy glue from seeping onto the visible grain, which can be difficult to clean.

Edge Finishing Techniques

Creating a beautiful, smooth edge on a textured piece is the final touch that signals true quality. The uneven surface requires a slightly different approach than a smooth hide.

When sanding, your first goal is to create a flat, uniform plane across the layers, even if the surface isn't perfectly smooth yet. Start with a medium-grit sandpaper (around 220-320) and work your way up. For most chrome-tanned pebble leathers, a high-quality painted edge provides the cleanest and most durable finish. For vegetable-tanned pebble, burnishing is still an excellent option. After sanding, apply your burnishing agent (like Tokonole) and use a canvas cloth or wood slicker with firm, consistent friction to meld the fibers into a glossy, sealed edge.

Feeling confident? Now you have the techniques to tackle any project. If you ever need advice on the right tools or leather for your next creation, we're always here to help at hab-to.com.

Your Journey with Pebble Leather Starts Here

You've now journeyed through the distinctive world of pebble leather, from understanding the difference between natural shrinking and mechanical embossing to learning the best techniques for cutting and stitching its unique surface. The key takeaway is clear: the right material is the heart of any great project. A high-quality leather pebble hide doesn't just add a beautiful, resilient texture; it elevates your craftsmanship and ensures your creation will last for years to come.

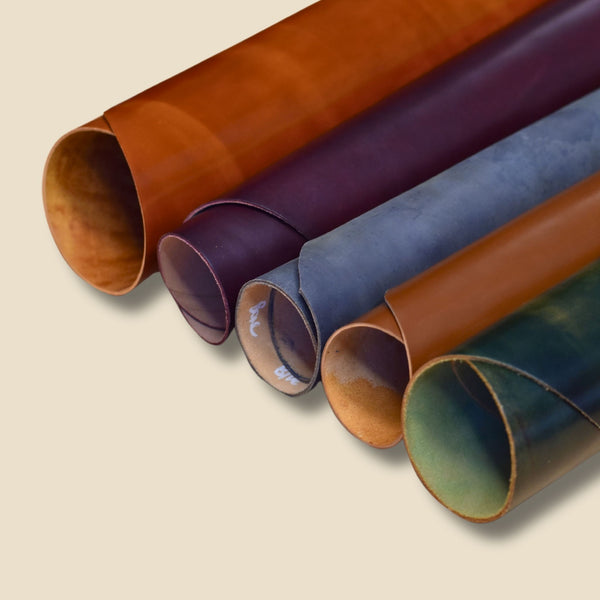

Now, it's time to turn that knowledge into something tangible. At Hab-To, our family's passion for leather has been passed down for over 160+ years, and we personally stand by every hide we offer. We focus on sustainable, premium quality and believe creativity shouldn't be limited by quantity, which is why we have no minimum order requirements. Find the perfect material for your vision. Browse our hand-selected pebble leathers for your next project.

Your next masterpiece is just a hide away. Happy crafting!

Frequently Asked Questions About Pebble Leather

Is pebble leather considered high quality?

Absolutely, but its quality depends on the underlying hide. High-quality pebble leather starts as full-grain or top-grain leather before a heavy press embosses the signature texture. This process can cleverly conceal minor imperfections on the hide's surface without compromising its integrity. So, when you choose a premium leather pebble hide, you are getting a material that is both durable and stylish, combining the best of natural leather with a resilient, uniform finish.

Does the pebbled texture wear off or flatten over time?

The embossed texture on quality pebble leather is remarkably durable and holds its shape well. It is pressed into the leather fibers under immense pressure, making it a permanent feature. While extreme and prolonged friction-for example, on the corner of a daily-used wallet-may slightly smooth the highest points of the grain over many years, the texture will not flake, peel, or simply wear off. It's a finish built to last through consistent use.

Can you tool, stamp, or carve on pebble leather?

Pebble leather is not suitable for tooling, stamping, or carving. These traditional leathercraft techniques require a smooth, firm surface to achieve a clean and detailed impression. The pre-existing embossed texture of pebble leather interferes with the tools, resulting in a distorted and unclear design. For this type of detailed work, we always recommend using a smooth vegetable-tanned tooling leather, which is specifically designed to hold intricate patterns and carvings beautifully.

What is the difference between pebble leather and Togo leather?

While they look similar, the key difference is how the texture is achieved. Pebble leather is a general term for leather that has been embossed with a pebble-like pattern by a heavy steel press. Togo, on the other hand, is a specific type of high-end calfskin from a French tannery. Its pebbled grain is natural, a result of a specific shrinking process during tanning, not embossing. Togo is prized for its softness, scratch resistance, and natural grain.

How do I clean and condition pebble leather goods?

First, wipe away dust with a soft, dry cloth. For light dirt, use a slightly damp cloth, moving in gentle circles. The pebbled texture can trap grime, so a soft-bristled brush can help lift it out. Always test any leather cleaner on a hidden spot first. Afterwards, apply a small amount of a quality leather conditioner with a clean cloth to moisturize the hide and keep it from drying out, which preserves its supple feel.

Is pebble leather waterproof?

No leather is truly 100% waterproof, as it is a porous, natural material. However, the finished surface of pebble leather offers excellent water resistance. The texture and protective coating cause water droplets from light rain to bead up and roll off rather than immediately soaking in. If your item does get saturated, allow it to air dry naturally away from direct heat sources like radiators or sunlight to prevent it from becoming stiff.