What is Tokonole? The Ultimate Guide to Perfect Leather Edges

There's nothing more frustrating than pouring hours into a beautiful leather project, only to be let down by edges that look fuzzy, frayed, and unprofessional. That smooth, glass-like finish you see on high-end leather goods can feel like an impossible standard to reach, the one detail that separates good craftsmanship from truly great craftsmanship. It’s a common struggle, whether you're just starting or have been at the bench for years.

But what if I told you the secret to that impeccable, durable edge often comes in a small, unassuming jar? For countless seasoned artisans, the key is a remarkable Japanese burnishing compound called Tokonole. It’s a game-changer, but knowing how and why to use it is crucial.

In this ultimate guide, we’re demystifying this workshop essential. You'll learn exactly what Tokonole is, how it differs from water or Gum Tragacanth, and most importantly, the step-by-step process to apply it for a flawless, professional finish. Say goodbye to guesswork and hello to strong, beautiful edges that elevate the quality of your work every single time.

What is Tokonole and Why is it a Leathercraft Essential?

If you've ever admired a piece of leatherwork with impossibly smooth, glassy edges, you've likely seen the magic of Tokonole. Hailing from Japan, this water-based burnishing gum is a game-changer for crafters at every level. Its primary purpose is to take the raw, fuzzy edges of vegetable-tanned leather and transform them into a durable, professional, and beautifully polished finish. Think of it as the final step that separates good craftsmanship from great craftsmanship.

Unlike simple glues or water, this compound contains a blend of natural waxes that penetrate, seal, and protect the leather fibers. It’s the secret weapon for achieving that premium look and feel. To see it in action, watch this helpful tutorial:

The Science Behind a Perfectly Burnished Edge

A raw leather edge is essentially a collection of loose, frayed collagen fibers. When you apply Tokonole, it soaks into these fibers, acting as a binding agent. The real transformation happens when you introduce friction with a wood slicker or canvas cloth. This friction generates heat, which melts the natural wax in the formula, effectively gluing and compacting the fibers into a single, solid unit. The result is a smooth, sealed, and polished surface that is both beautiful and resilient.

Key Benefits of Using Tokonole in Your Projects

Integrating this burnishing gum into your workflow offers several distinct advantages that elevate the quality of your work:

- Aesthetics: It creates a high-end, glossy finish that immediately signals quality and attention to detail. This is the look that high-end brands are known for.

- Durability: By sealing the leather fibers, it protects the edges from fraying and absorbing moisture over time, significantly increasing the lifespan of your project.

- Feel: A burnished edge is incredibly smooth to the touch, enhancing the user experience of a wallet, belt, or bag. No more rough, scratchy edges.

- Versatility: Its use isn't limited to edges. You can also apply a thin layer to the flesh (fuzzy) side of leather to smooth it down, creating a clean and finished interior surface.

How to Use Tokonole: A Step-by-Step Guide for a Glass-Like Finish

Achieving that coveted, glass-like edge is a hallmark of fine leather craftsmanship, and it's more accessible than you think. The process is a rewarding ritual that transforms a raw edge into a durable, polished seal. While the history of Tokonole reveals its Japanese origins as a professional-grade compound, its application is straightforward with the right technique and a bit of patience. Before you begin, gather your essential tools.

- Tokonole Burnishing Gum: The star of the show. Remember, a little goes a very long way.

- Applicator: Your finger is often the best tool, but a small cloth or wool dauber also works well.

- Burnisher: A multi-groove wood slicker is ideal, but a piece of heavy canvas or denim can also produce great results.

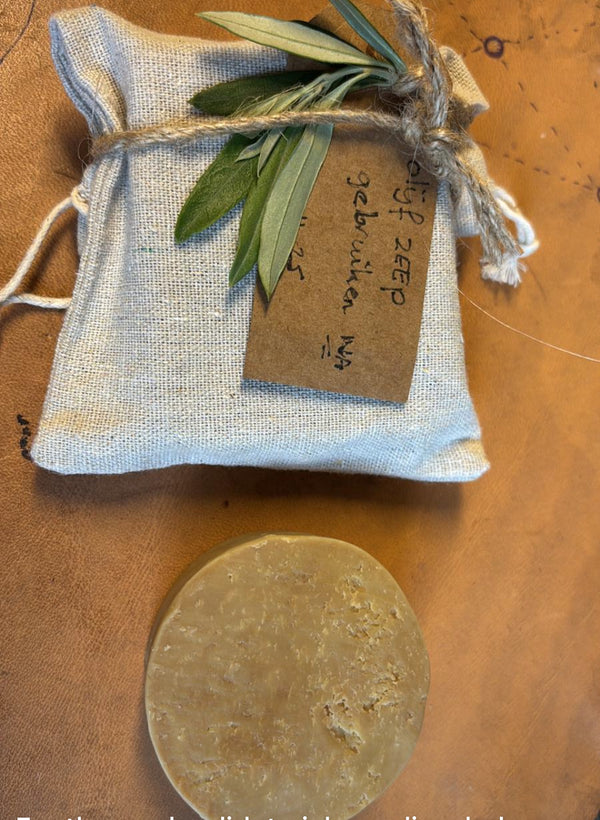

Step 1: Preparing Your Leather Edge

A perfect finish starts with a perfect foundation. Begin with a clean, uniformly cut edge. If you're working with multiple layers, ensure they are glued together flush. Use a sharp knife or an edge beveler to create a smooth, slightly rounded profile. Next, sand the edge to remove any fuzz or imperfections. Start with a lower grit sandpaper (like 220) and progress to a finer grit (400-600) for a silky-smooth surface. Wipe away any lingering dust with a damp cloth before moving on.

Step 2: Applying a Thin, Even Coat

Dispense a very small amount of Tokonole onto your finger or applicator. Spread it along the leather edge in a thin, even layer, working it gently into the fibers. It's best to work in manageable sections, perhaps 10-15 cm at a time, to prevent the compound from drying out before you can burnish it. Be careful to keep the product on the edge itself, avoiding any excess on the grain or flesh side of your leather.

Step 3: Burnishing to a High Shine

While the edge is still slightly damp, it's time to burnish. Using your wood slicker or canvas cloth, apply firm, consistent pressure and move it quickly back and forth along the edge. This friction generates heat, which activates the waxes and resins in the Tokonole, compressing the leather fibers and creating a tight, sealed surface. You'll see the edge darken slightly and begin to develop a beautiful, glossy shine. Continue until the edge feels smooth and slick to the touch.

Step 4: Repeat for Perfection (Optional)

For an unparalleled, mirror-like finish, a second pass can elevate your work. Allow the first layer to dry completely (about 10-15 minutes). Lightly sand the edge with a very high grit sandpaper (800 or higher) to create an even smoother surface. Then, apply another whisper-thin layer of burnishing gum and repeat the burnishing process. This second application fills any remaining microscopic pores, resulting in a flawless edge. Find the perfect burnishing tools for your project at Hab-To.

Tokonole vs. Gum Tragacanth: A Head-to-Head Comparison

In the world of leathercraft, the debate between modern solutions and traditional methods is a constant. When it comes to burnishing, the two main contenders are Tokonole and Gum Tragacanth. For decades, Gum Tragacanth was the go-to for sealing leather edges—a natural, time-tested product that has served crafters well. But how does this classic staple stack up against its popular Japanese counterpart?

While both aim to give you a smooth, professional edge, their composition, application, and final results are quite different. Let's break it down.

Composition and Finish

The most significant difference lies in what they're made of. Gum Tragacanth is a natural gum, a sap derived from the Astragalus gummifer shrub. It produces a clean, durable, and semi-glossy or satin finish that many traditional crafters appreciate. Tokonole, on the other hand, is a proprietary water-based formula that includes waxes. This special blend allows it to create a much higher-gloss, almost glass-like finish. Its unique composition also means you can often achieve that final polish with fewer applications, saving you time at the bench.

Ease of Use and Drying Time

For sheer convenience, Tokonole often has the edge. It comes ready to use right out of the jar, with a smooth, consistent viscosity that’s easy to apply. It also offers a generous working time before it starts to dry, making it more forgiving. Gum Tragacanth can sometimes be very thick and may require thinning with a bit of water for a smooth application. It also tends to dry faster, which can be a challenge if you're new to the process. Many crafters find Tokonole feels slicker under the burnisher, whereas Gum Tragacanth can have a slightly 'gummy' feel during application.

Tokonole

- Finish: High gloss, glass-like

- Composition: Proprietary blend with waxes

- Application: Ready to use, smooth

- Working Time: Longer, more forgiving

- Best For: Beginners, high-shine projects

Gum Tragacanth

- Finish: Satin to semi-gloss

- Composition: Natural plant-based gum

- Application: May require thinning

- Working Time: Shorter, dries faster

- Best For: Traditionalists, natural finishes

Final Recommendation: Which Should You Use?

So, which one belongs in your workshop? There's no single right answer—it depends on your goals and philosophy.

- For Beginners: We almost always recommend Tokonole. It's incredibly user-friendly, forgiving, and delivers consistently beautiful, high-gloss results with minimal fuss.

- For Traditionalists: If you value all-natural materials and the time-honoured methods of the craft, Gum Tragacanth is an excellent choice that has proven its worth for generations.

- For the Ultimate Gloss: If your project demands a mirror-like, glossy edge, there's no contest. Tokonole is the clear winner for achieving that premium, polished look.

Ultimately, both are fantastic products. The best way to decide is to try both and see which one fits your workflow and aesthetic best. No compromises, just the right tool for the job.

Pro Tips and Troubleshooting for a Flawless Finish

You've mastered the basics, and your edges are looking good. Now, let's elevate your craft from good to exceptional. Achieving that glass-like, professional burnish is a matter of refining your technique and knowing how to solve the little problems that pop up along the way. Here at Hab-To, we believe in real craftsmanship, and that means paying attention to the details.

Troubleshooting Common Issues

Even seasoned crafters run into issues. The key is knowing why it happened and how to fix it. Here are the most common burnishing hurdles and their solutions:

- The edge feels sticky or gummy: This is a classic sign of using too much product. Remember, a thin, even layer is all you need. Scrape off the excess with a clean tool, let it dry, and try burnishing again. Less is truly more.

- The finish looks dull or hazy: A lackluster finish usually comes down to a lack of friction. You need to generate a bit of heat. Increase your speed and apply firm, consistent pressure. The shine comes from compressing and polishing the leather fibers, not just from the product itself.

- A white residue appears: If you see a chalky film, don't panic. This just means the Tokonole hasn't fully absorbed and dried. Let the edge air dry completely for another 10-15 minutes, then buff it vigorously with a soft, clean canvas or denim cloth. The residue will polish away, revealing a clear shine.

Advanced Techniques and Creative Uses

Once you're comfortable with edge work, you can explore the full potential of this versatile compound. These techniques can save time and add a premium, custom touch to your projects.

- Use a Powered Burnisher: For speed and consistency, nothing beats a powered burnisher attached to a Dremel or drill press. The high RPMs generate heat quickly, creating a flawless, glassy edge in seconds. Just be sure to use a light touch to avoid burning the leather.

- Finish the Flesh Side: Apply a thin layer to the fuzzy flesh side of a piece of leather and slick it down with a glass slicker. This tames the fibers, creating a smooth, durable surface that feels almost like a lining—perfect for unlined wallets, straps, and cases.

- Match or Contrast with Color: Use black or brown Tokonole to create a seamless, uniform look on dyed edges or to add a subtle, professional contrast to natural veg-tan. It burnishes just as beautifully as the clear version.

- Lock in Edge Paint: After your edge paint has completely cured, apply an extremely thin coat of clear burnishing gum over the top. Burnish it gently with a cloth to create a durable, semi-gloss top coat that protects the paint from chipping and wear.

Need advice on the right tools for the job? Feel free to get in touch with us for a personal consultation.

Understanding Tokonole's Performance on Different Leathers

One of the most common points of frustration for new leatherworkers is trying to achieve a perfect edge, only to get lackluster results. The secret isn't always in the technique—it's often in the leather itself. Tokonole is a phenomenal product, but its performance is directly linked to the leather's fiber density. Understanding this relationship is key to mastering your craft and setting realistic expectations for every project.

The effectiveness of any burnishing agent depends on its ability to penetrate, lubricate, and compress the leather's collagen fibers. When these fibers are dense and tightly packed, they can be compacted and polished into a hard, smooth surface. When they are loose, the results will be different. Let's break down what to expect.

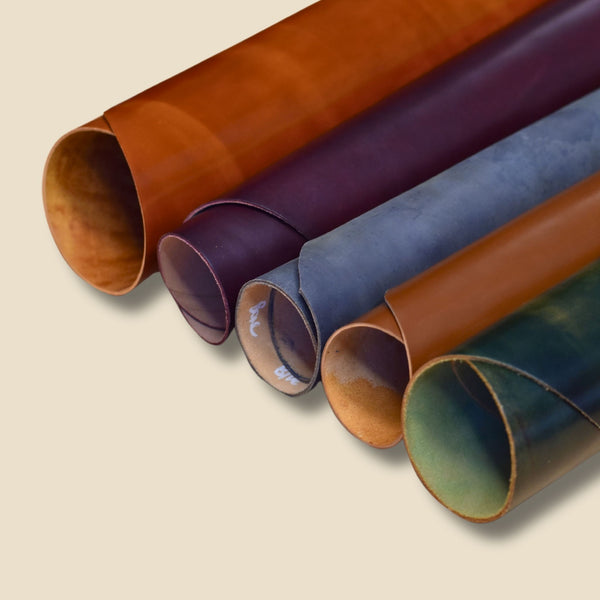

The Perfect Match: Vegetable-Tanned Leather

There's a reason you see vegetable-tanned leather in nearly every burnishing tutorial. Its traditional tanning process creates a firm leather with a dense, tight fiber structure. This is the ideal canvas for burnishing. The water-based Tokonole penetrates the exposed fibers, and the friction from your slicker melts the wax, compacting everything into that coveted hard, glass-like edge. For that signature finish, veg-tan is the undisputed champion. To achieve these premium results, you need premium materials. Browse our premium selection of vegetable-tanned leathers.

Working with Chrome-Tanned and Oily Leathers

Chrome-tanned leather has a different fiber structure—it's often softer, more flexible, and less dense. Think of it as more 'spongy'. While you can still use a burnishing gum to smooth the edge and knock down the fuzz, you will rarely achieve the same hard, glossy finish as with veg-tan. The fibers simply don't have the same structure to compact so rigidly.

- For Chrome-Tan: Often, a high-quality edge paint is a better and more durable solution for finishing chrome-tanned goods, creating a sealed, professional look.

- For Oily/Waxy Leathers: Leathers with a high oil or wax content (like Chromexcel or waxed pull-up) can resist water-based products. The oils can prevent the burnishing gum from absorbing properly, resulting in a weak or ineffective burnish.

Choosing the right finishing method for your leather type is a hallmark of true craftsmanship. It shows a deep respect for the material and ensures a beautiful, long-lasting final product.

Your Journey to Flawless Leather Edges

Mastering the art of edge finishing is a true mark of a dedicated leather crafter. As we've covered, it's a process that transforms your work from simply handmade to truly professional. You've learned how a high-quality compound like Tokonole can create a durable, glass-like shine and how crucial proper preparation and technique are to achieving that flawless result. The difference between a good project and a great one often lies in these final, polished details.

At Hab-To, we believe that real craftsmanship starts with materials you can trust. With over 160 years of family experience, we bring a passion for quality to everything we do. Our supplies are hand-selected because we make no compromises on quality. And with no minimum order requirements, we're here to support every crafter, from your first project to your hundredth. Ready to perfect your edges? Shop our leather finishing supplies.

Now it's your turn to put this knowledge into practice. Take your time, enjoy the process, and create something you're truly proud of. Happy crafting!

Frequently Asked Questions About Tokonole

Is Tokonole waterproof?

While Tokonole provides excellent water resistance, it is not fully waterproof. It creates a smooth, sealed edge that can repel light moisture and splashes, protecting the leather fibres from minor water exposure. For projects that will face heavy rain or submersion, we recommend applying a dedicated waterproof topcoat, such as a beeswax compound or an acrylic resolene, after the edge has been fully burnished and dried. This ensures the highest level of protection for your quality craftsmanship.

Does Tokonole expire or go bad?

Tokonole has a very long shelf life but can degrade over time. If stored properly with the lid tightly sealed in a cool, dark place, it can last for several years. You will know it's time for a new bottle if you notice a foul smell, significant colour change, or if the compound has dried out or separated to a point where it cannot be mixed back to a smooth consistency. A good product is key to a premium finish.

Can you dye or paint over a Tokonole-finished edge?

It is best to dye your edges before applying Tokonole. This burnishing compound works by creating a smooth, sealed, and non-porous surface. Because of this protective layer, leather dyes and edge paints will not be able to penetrate or adhere properly and will likely crack or flake off over time. For a durable, professional finish, always complete your dyeing process first, let it dry completely, and then proceed with burnishing for that perfect, glossy edge.

What's the difference between clear, black, and brown Tokonole?

The core burnishing function is the same across all colours; the only difference is the added pigment. Clear Tokonole is the most versatile and can be used on any colour of leather without altering its shade. The black and brown versions contain pigment, making them ideal for finishing the edges of corresponding black and brown leathers. They are excellent for creating a uniform, solid-coloured edge and can help conceal any minor imperfections from the cutting or sanding process.

Do I absolutely need to sand my edges before using Tokonole?

For a truly professional, glass-like finish, yes, we highly recommend sanding. While you can get a decent result without it, sanding creates a smooth, uniform foundation for the Tokonole to work its magic. It removes loose fibres and evens out any high spots from cutting. Starting with a medium grit (around 220-400) and moving to a fine grit (600-800) will give you a superior result. Remember, quality craftsmanship starts with proper preparation.

How do I clean up Tokonole if I spill it or get it on the leather face?

Act quickly! Since Tokonole is water-based, the best way to clean up a spill on the leather face is with a clean, damp cloth. Gently wipe the excess away immediately, being careful not to rub it further into the grain. If it dries, it can leave a slight sheen or darken lighter leathers, especially natural vegetable-tanned hides. For spills on your work surface, a simple wipe with a wet cloth will do the trick. Prompt cleanup is key.

Can I use a piece of denim or canvas instead of a wood slicker?

Absolutely. While a wood slicker is a fantastic and efficient tool, many experienced crafters achieve a beautiful, high-gloss finish using a simple piece of heavy canvas or denim. The key is generating friction and a bit of heat to work the compound into the leather fibres and polish the edge. Just wrap the fabric tightly around your finger or a small block of wood and burnish vigorously. It's a great, accessible method that delivers professional results.